What we do

Specialty stainless steel processes (S³P)

Specialty stainless steel processes (S³P) featuring Kolsterising® technology offer unique surface hardening solutions for austenitic stainless steel, nickel-based alloys and cobalt-chromium alloys producing increased mechanical and wear properties without adversely affecting corrosion resistance.

The ultimate protection for stainless steel.

Low temperature-based process

Microhardness

Our largest capacity

Diffusion depths

Key benefits of Specialty stainless steel processes (S³P)

Eliminates wear, galling and fretting

description sentance to come…

No dimensional change

description sentance to come…

Improved fatigue strength

description sentance to come…

No risk of delamination

description sentance to come…

Low-temperature, distortion-free process

description sentance to come…

Austenitic stainless steel parts improve their mechanical properties by applying the S³P processes, resulting in hardened austenitic stainless steel surfaces. In all S³P processes, the corrosion of the base material is not altered, while exhibiting superior wear resistance, strength and ductility, as well as resistance to galling. As surface diffusion processes, the surfaces do not crack or chip, offering significant advantages over coating technologies. S³P A® and Kolsterising® are the state of the art processes for austenitic stainless steel, duplex stainless and nickel-based materials. S³P M is used for the treatment of martensitic and precipitation hardened stainless steel materials.

S³P treatments involve low temperature diffusion of large quantities of carbon and/or nitrogen into the surface without the formation of chromium precipitations. No additional chemical elements that were not already present prior to the treatment are introduced during the process. There is no risk of delamination because S³P processes neither add a coating nor introduce brittle phases in the material.

The premier, industry-proven innovation for hardening stainless steel – without loss of corrosion resistance – and is only available from Bodycote.

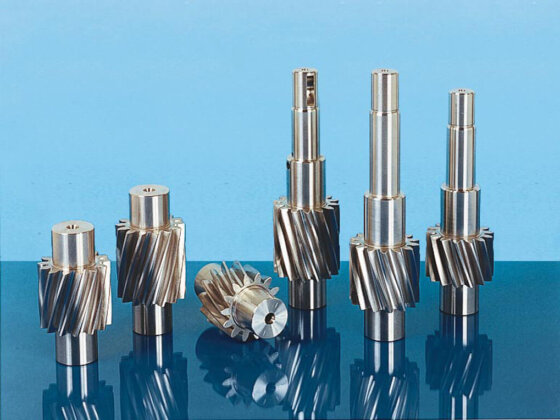

Applications

S³P processes are used for products across a wide range of markets from precision medical tools to automotive components.

Here are some links to more information about how S³P delivers superior material properties: