What we do

Hot isostatic pressing

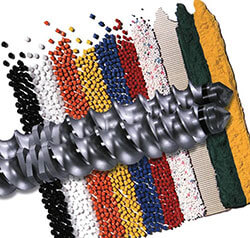

Hot isostatic pressing (HIP) is a form of heat treatment that uses high pressure to improve material properties. That pressure is applied by an inert gas, usually argon. Time at elevated temperature and pressure allows plastic deformation, creep and diffusion to occur. Castings for critical applications are HIPed to eliminate internal microporosity thereby improving mechanical properties by removing defects. Hot isostatic pressing also enables the bonding, or cladding, of two or more materials together, either in the solid or powder form.

Hot Isostatic Pressing with high heat and pressure, transforms metal into 100% dense solid material

Our number of vessels

Our highest temperature capability

Our tallest vessel

Our maximum pressure

Key benefits of Hot Isostatic Pressing

Improve integrity

Elimination of internal porosity in castings

Design smarter

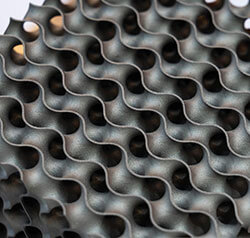

Densification of ceramic, metal or composite powders, e.g. post 3D printing

High-Strength Bonds

Diffusion bonding of multiple/dissimilar alloys – powder & solid

Realise real value

Cost-effective, near net complex shape product manufacture

Improved properties

Stronger, more durable components with better fatigue life & homogeneity

Hot isostatic pressing plays an important role in powder metallurgy and 3D printing as well. Bodycote has decades of experience creating both simple to complex components from powdered metal. Bodycote Powdermet® technologies are a group of manufacturing processes used in the production of complex components; and now incorporate new, patent-pending techniques that combine 3D printing with well-established near net shape and selective surface net shape techniques. These solutions dramatically reduce the manufacturing time and production cost of a part compared to producing the same part using 3D printing alone.

As the global leader in specialist thermal processing, Bodycote offers an extensive range of hot isostatic pressing services. Our facilities process a wide variety of component sizes to exacting standards with reliable, repeatable results.

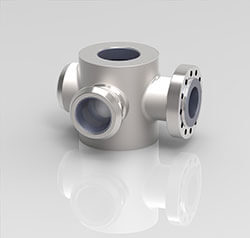

Bodycote specialises in high-integrity parts for the world’s most demanding applications in Subsea, Offshore, and Nuclear

Our services

Powdermet® manufacturing technologies

Isostatic pressing services

HIP supporting services

Component journeys

Examples of parts HIPed in large volumes include, but are not limited to: Hot section and structural gas turbine components (both dynamic and static); aerospace structural and engine parts; implantable medical devices; automotive engine components; valve bodies and other petrochemical processing equipment; critical munitions pieces; tooling, die and general engineering parts; sputter targets; and PM alloy billets and near net shapes (NNS).

Here are some example component journeys showing how HIP delivers superior material properties: