What we do

Specialty stainless steel processes (S³P)

Specialty stainless steel processes (S³P) featuring Kolsterising® technology offer unique surface hardening solutions for austenitic stainless steel, nickel-based alloys and cobalt-chromium alloys producing increased mechanical and wear properties without adversely affecting corrosion resistance.

The ultimate protection for stainless steel.

Low temperature-based process

Microhardness

Our largest capacity

Diffusion depths

Key benefits of Specialty stainless steel processes (S³P)

Eliminates wear, galling and fretting

Delivers long-lasting protection and smooth functionality under the most demanding conditions.

No dimensional change

Delivers enhanced performance without compromising precision.

Improved fatigue strength

Provides superior resistance to wear from repeated stress.

No risk of delamination

Ensures a stable, long-lasting surface with no flaking or peeling.

No loss of corrosion resistance

Corrosion performance is preserved, delivering lasting protection without trade-offs.

Austenitic stainless steel parts improve their mechanical properties by applying the S³P processes, resulting in hardened austenitic stainless steel surfaces. In all S³P processes, the corrosion of the base material is not altered, while exhibiting superior wear resistance, strength and ductility, as well as resistance to galling. As surface diffusion processes, the surfaces do not crack or chip, offering significant advantages over coating technologies. S³P A® and Kolsterising® are the state of the art processes for austenitic stainless steel, duplex stainless and nickel-based materials. S³P M is used for the treatment of martensitic and precipitation hardened stainless steel materials.

S³P treatments involve low temperature diffusion of large quantities of carbon and/or nitrogen into the surface without the formation of chromium precipitations. No additional chemical elements that were not already present prior to the treatment are introduced during the process. There is no risk of delamination because S³P processes neither add a coating nor introduce brittle phases in the material.

The premier, industry-proven innovation for hardening stainless steel – without loss of corrosion resistance – and is only available from Bodycote.

Which S³P process is right for you?

FAQs: K22, K33, K Duplex

The low temperature carbon diffusion treatment is based on the proprietary Kolsterising® process. The different processes K22, K33 and K Duplex mainly differ in their diffusion depth, the proprietary physical principle is the same.

Beside the chemical composition of the alloy, the results are also dependent on heat treatment and machining.

The appearance after the process is dependent on the delivery condition of the part.

The passive layer has the best properties when the microstructure of the base material is uniform. Non-uniformities like sulfides, deformation martensite and delta ferrite might reduce the corrosion resistance.

Beside the chemical composition of the alloy, the results are also dependent on heat treatment and machining.

FAQs: S³P M, S³P A and S³P D

The proprietary low temperature nitrogen and/or carbon diffusion treatments are based on S³P technology. The different processes S³P M (Martensitic), S³P A (Austenitic) and S³P D (Duplex) are designed to meet the special needs of the different alloy groups.

Beside the chemical composition of the alloy, the results are also dependent on heat treatment and machining.

Please send a drawing including information about heat treatment to check technical feasibility.

The passive layer has the best properties when the microstructure of the base material is uniform. Non-uniformities, like sulfides, reduce the corrosion resistance.

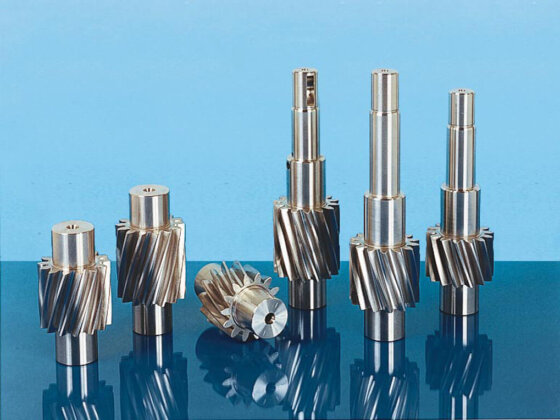

Applications

S³P processes are used for products across a wide range of markets from precision medical tools to automotive components.

Here are some links to more information about how S³P delivers superior material properties: