What we do

Powdermet®

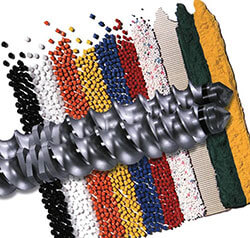

Bodycote has decades of experience creating complex, high integrity components from powdered metal. Bodycote Powdermet® technologies are a group of manufacturing processes used in the production of complex components using powder metallurgy.

Bodycote Powdermet® technologies now incorporate new, patent-pending techniques that combine 3D printing with well-established net shape and near net shape techniques. This new technology dramatically reduces the manufacturing time and production cost of a part compared to producing the same part using 3D printing alone.

Bodycote’s Powdermet® processes involve innovative materials science, enabling versatility and flexibility beyond the scope of traditional manufacturing

meters of Powdermet® bimetallic bars

Largest Powdermet® item made to date

Subsea welds eliminated

Tonnes of powder used

Key benefits of Powdermet®

Unique isotopic properties

Built Strong. In Every Direction. Our process eliminates directional weakness for truly isotropic performance

High-Strength

Bonds

Diffusion bonding of multiple/dissimilar alloys – powder & solid

Realise real

value

Cost-effective, near net complex shape product manufacture

Design

smarter

Densification of ceramic, metal or composite powders, e.g. post 3D printing

Improved surface

finish

HIP engineered Ultra clean powder metals improves surface finish and fatigue strength durability

Powdermet® technologies ensure complete powder consolidation, achieve structural homogeneity, and eliminate internal porosity and unconsolidated powder flaws. The process can produce components with varying surface features and thicknesses, with higher structural integrity than alternative production techniques. The need for brazing or welding parts together to form larger structures is eliminated. Instead, the finished article can be produced as one seamless component and largely avoid the size limitations imposed by the constraints of 3D printing. Different parts of a component can be formed from different alloys presenting the ideal and most cost-efficient solution. Component design can be tailored to the actual requirements for performance and not limited by subsequent machining operations.

With the design flexibility of Bodycote’s Powdermet® processes, complex components and material characteristics can be achieved which are not possible with conventional manufacturing methods.

Our products and services

Powdermet® - Near net shape (NNS)

Simple shape

Component journeys

Examples of parts…

Here are some example component journeys showing how Powdermet® delivers superior material properties:

Our expertise

Our Powdermet® operations are managed by some of the best engineers and technicians in the industry, with the experience and expertise to provide vital support and a real understanding of customer requirements.