Bodycote is the world’s largest service provider of heat treatment and specialist metallurgical technologies.

Our technologies are vital to the safe and effective working life of thousands of components. Our global network of engineers and metallurgists collaborates with customers to solve complex materials challenges, enhance operational efficiencies and help reduce carbon emissions. Our services allow our customers’ parts to achieve optimal performance and reduce their environmental impact, supporting a more sustainable future.

What we do

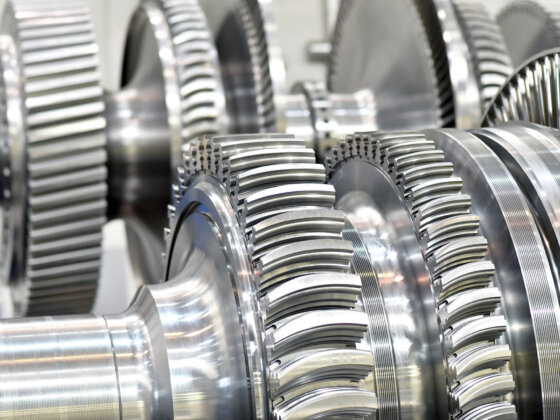

Virtually every type of metal component, whatever its application, requires some form of treatment to enable it to perform to the necessary standard and last longer once it’s put into service.

Our metallurgical treatments improve the properties of metals and alloys, enabling our customers’ products to perform optimally in both critical and everyday applications that enable modern life.

Precision Heat Treatment

An expansive portfolio of vital heat treatment services and low-carbon technologies which enable components to excel in any environment, for longer. We process a wide variety of component sizes to exacting standards with reliable, repeatable quality output from one-offs to volume production, with consistent delivery that ensures near-zero scrap rates.

Surface Technology

Our range of surface coatings, including ceramics and metallics, enhance component life and provide ultimate protection from wear and corrosion. Combined with sealing solutions, precision finishing and in-house laboratories, Bodycote provides a full turnkey coatings service.

Hot Isostatic Pressing (HIP)

HIP improves component integrity and strength by application of extreme pressure and heat to fully remove porosity in materials. Bodycote operates the largest HIP network in the world and is able to accommodate large volumes of small product as economically as large individual components.

Powdermet®

Bodycote has decades of experience creating complex, high integrity components from powdered metal. Bodycote Powdermet® technologies are a group of manufacturing processes used in the production of complex components using powder metallurgy.

S³P

S³P (Specialty Stainless Steel Processes) is a propriety group of Bodycote processes which improve the strength, hardness and wear resistance of stainless steels without affecting their corrosion resistance.

Metal Joining

Bodycote has a wealth of experience in delivering value-adding and innovative metal joining techniques such as Electron Beam Welding, HIP diffusion bonding and various methods of brazing for safety critical components.

We understand your challenges

Bodycote has a long and successful history of working together with customers to provide performance solutions for virtually every issue.

Whether it’s extreme temperature resistance, the ability to withstand corrosion attack, or the ultimate protection for stainless steel, Bodycote has delivered some of the most innovative and technologically advanced materials solutions available, giving our customers the competitive edge.

View our global locations - over 150 Plants 22 Countries...

Why choose Bodycote?

Designed for

sustainability

Smarter processes, Smaller footprint. Designed to support your sustainability goals – our innovations can cut carbon emissions by up to 60%.

Latest News

Click here for press releases

or more news

B Carbon Smart

Did you know that Bodycote can help customers reduce carbon emissions per part by up to 60%?

Measurable results, real-world data, a proven track record. These are just some of the reasons that the world’s most forward-thinking companies choose to outsource to Bodycote. Our proprietary avoided emissions calculation tool helps our customers identify how much they could reduce emissions and improve operational efficiencies.

Bodycote customers around the world are reaping the benefits of more efficient processing, lower carbon technology, and lower emissions. That’s being carbon smart.

Investors

Creating value for our investors

We are focused on creating sustainable value for all our stakeholders, whether investors, customers, employees, or the communities where we operate.

Annual report 2024

Join Bodycote

Work with us

Whether you’re a metallurgist or a marketer, a furnace operator, or a finance clerk, we recognise that the success of our business depends upon the skills, commitment and loyalty of our people. Find out more about joining a team that really makes a difference…

Resource centre

Explore our world

Bodycote’s objective is to create superior shareholder returns through the provision of selected thermal processing services, on a global basis, that are highly valued by our customers. Bodycote aims to achieve this in a safe working environment and with minimal environmental impact.